Directed Energy Deposition

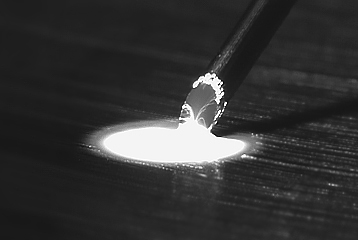

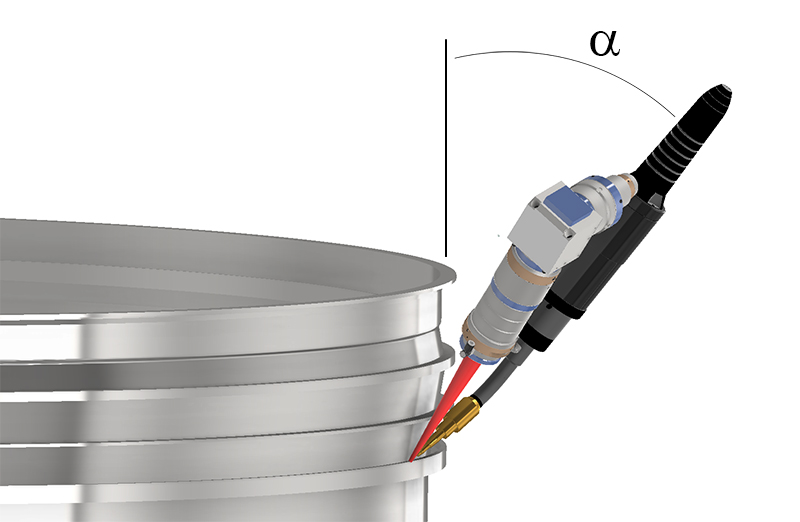

Directed Energy Deposition (DED) comprises of Additive Manufacturing techniques in which material is added to an existing component or surface. By utilizing a power source with high energy flux density, such as a laser or plasma arc, feedstock material in the form of either powder or wire is melted and fused. Through a relative motion between the processing tool and the surface, the molten material is solidified into beads which are deposited layer upon layer forming the 3D shape. When used with metals, the DED process is usually referred to as direct metal deposition or metal deposition for short.

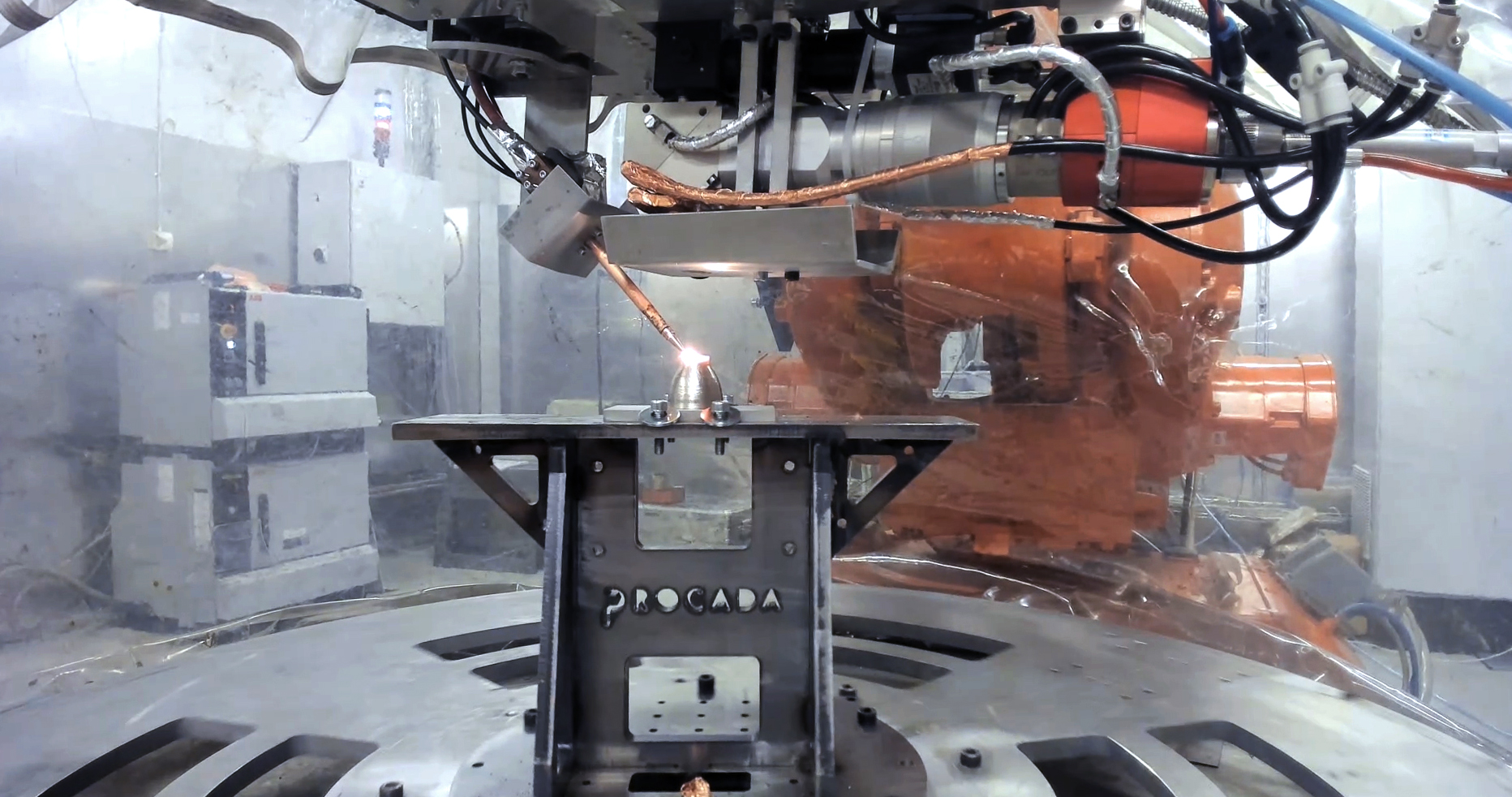

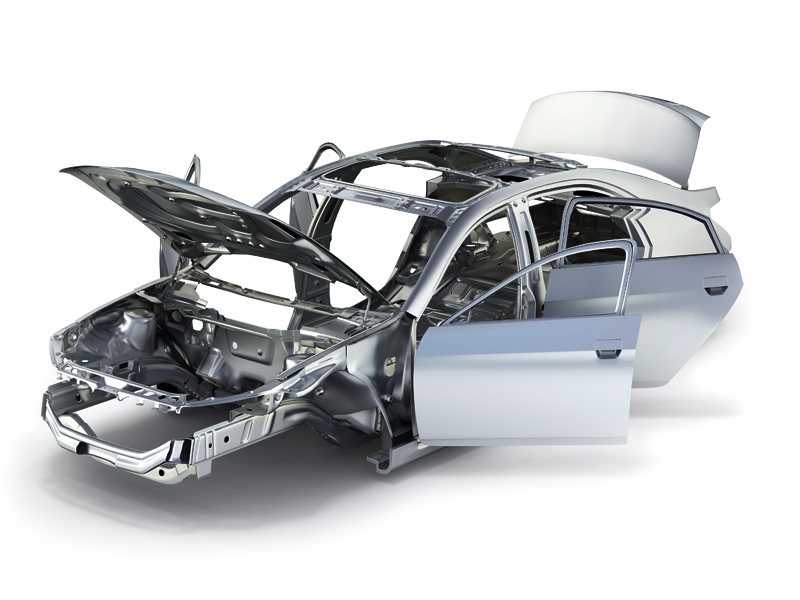

A typical DED machine consists of a processing tool attached to a multi-axis robotic arm or a gantry system. This offers a unique ability to add features onto components of arbitrary size and shape. The DED technology is therefore ideal for repair of worn parts or fabrication of new parts. In fabrication of new parts conventional manufacturing techniques can be combined with DED technology to enable an efficient use of different material forms as well as greater utilization of previously impractical-to-machine alloys. This offers new possibilities to weight reduction, higher operating temperatures and longer service life. A fabrication approach utilizing DED will also lead to substantial reduction in material utilization, number of parts, lead time and production cost.

Wire DED

Directed energy deposition comes to its full potential when combined with wire filler material as this offers several advantages compared to using powder feedstock. Some of the main benefits are:

- Fully dense parts

- 100% material utilization

- Simpler and safer material handling

- Lower feedstock cost

- Very high deposition rates

- Superior surface roughness

- Flexible deposition setup

- Less maintenance

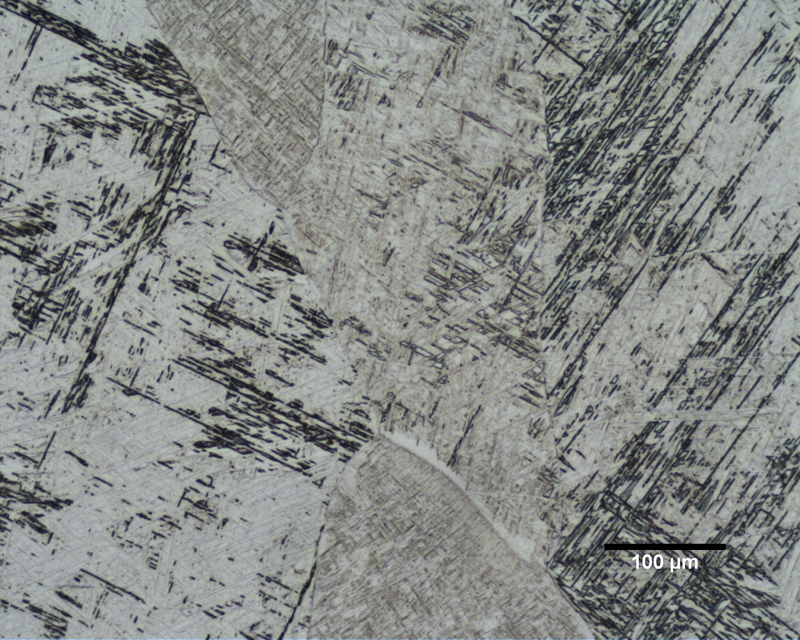

Non-optimal deposition parameters, contaminated feedstock material or process disturbances will result in porosity and in the end deteriorate the material properties. Although all AM techniques can in theory produce a fully dense structure, porosity is common in parts produced by powder-based processes while rare or non-existing for wire-based processes. This not only ensures consistent material properties throughout the part, but also eliminates the need for subsequent postprocessing such as High Isostatic Pressing (HIP).

Lack-of-fusion defects (flat cracks) are however equally common for both powder and wire DED if process parameters are poorly chosen or the deposition process experience disturbances which are not corrected for. With Procada’s closed loop control, we can ensure that the process is kept within the allowed process window at all times leading to reduced probability for lack-of-fusion defects and thereby consistent material quality.

Unlike powder-based additive manufacturing, where a large portion of the powder feedstock is either scattered during deposition (blown-powder processes) or not utilized at all (powder-bed processes), a wire based DED process utilizes all of the feedstock that is fed into the melt pool. Consequently, there is no need for subsequent handling of the unutilized material such as collecting powder for scrapping or possibly processing for later re-use. For high-value materials often found in metal AM, the excellent material utilization makes a significant impact both on your business case and the environment.

Powders need to be handled with care. Some metal powders are to be considered explosive if mixed with air and the fine powder particles are hazardous to both people and the environment. Because of this, handling of powders is associated with extra effort, cost and time when compared to wire. Wires are not considered to constitute a health risk and are not explosive nor a fire hazard in air.

Wires are also, when handled with appropriate gloves, not easily contaminated unlike powders. Wire can also be transferred to the processing point without the use of carrier gas.

Metal wire for weld metals is readily available from several suppliers and can generally be sourced at a lower cost per unit weight than powders. Further, by not needing carrier gases, the wire process is at an advantage to powder-DED when it comes to cost of consumables.

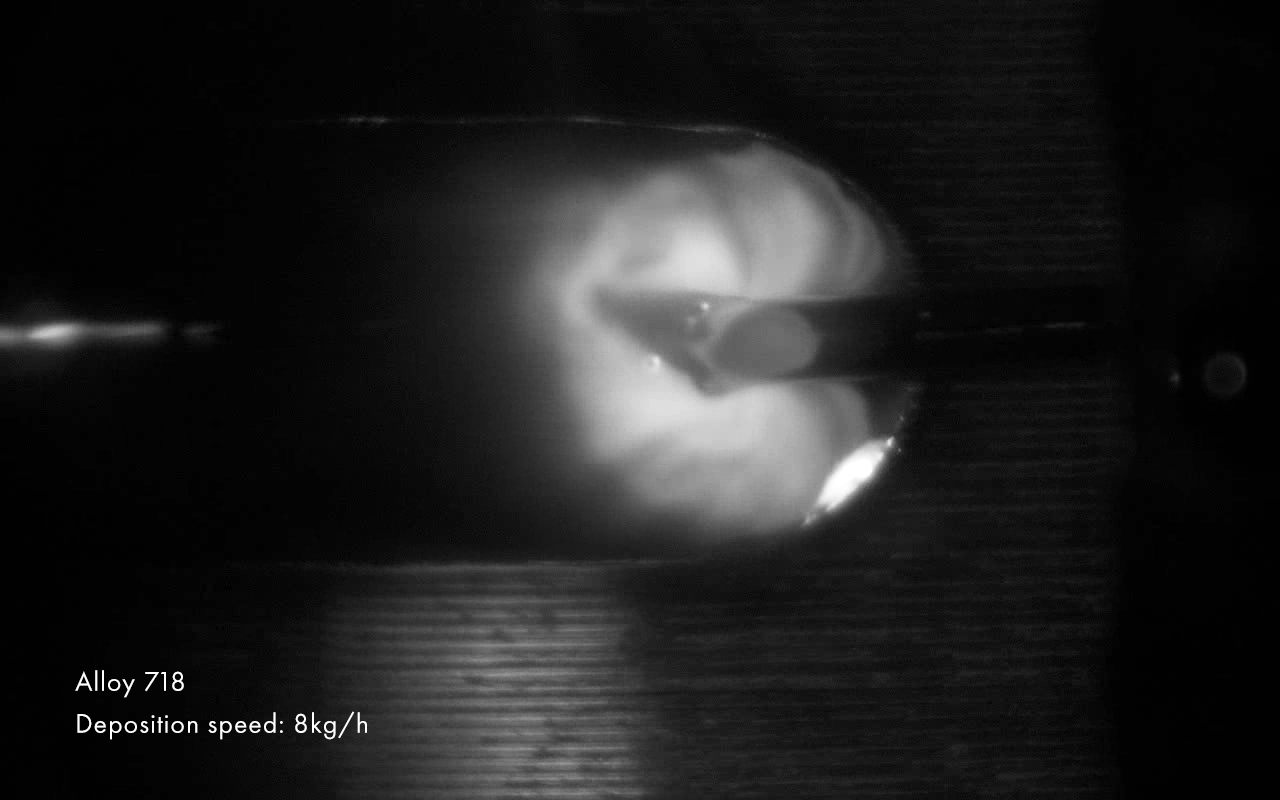

Due to the ability to feed current through the wire, preheating of the feedstock can be used to add extra energy and thereby allowing for higher deposition rates. This approach can increase the effective energy for melting material without the need for a more powerful primary power source such as a laser or electrical arc. In order to transfer a lot of material to the processing spot for very high deposition rates, one can either use wires with larger dimensions or use several wires in a parallel configuration.

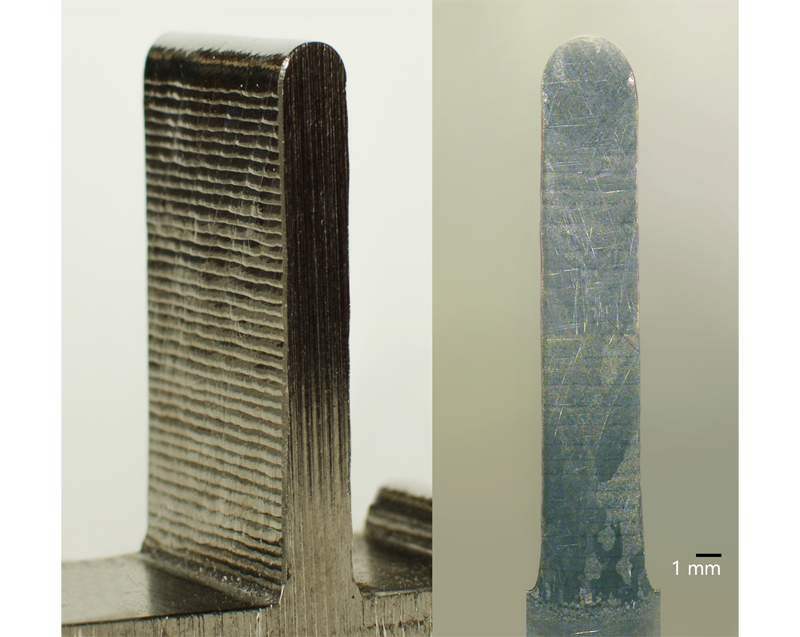

Wire processes typically result in low surface roughness compared to powder processes due to the absence of semi-molten entrapped particles. However, wire processes typically yield slightly “wavy” surfaces as a result of layers being placed on top of each other. It should be noted that this phenomenon is also present for powder-DED processes. The superior surface roughness of wire-DED parts lowers the risk for crack initiation compared to parts created by a powder process. The surface created by a wire process can in many applications be used as-deposited unless it constitutes a mechanical interface. This reduces the number of machining operations required for the finished part.

The wire is self-supporting and rigid as opposed to powders. This has the benefit that wire can be fed into the processing point independently of gravitation. This is an important trait when it comes to adding features on existing components with limited access and reorientation possibilities to suit the deposition process. A powder/gas stream in powder-DED on the other hand, can be operated only when close to parallel to the gravitational vector.

Just like powder-DED, wire-DED is capable of coaxial wire feeding making the system flexible in respect to the deposition pattern.

The use of wire as feedstock material benefits from the existing wire delivery systems developed for welding. These are more durable and cheaper to purchase and maintain than their powder counterparts.

Printing speed vs. part resolution

To fully exploit the benefits of wire-fed DED it is essential that consistent material properties can be ensured throughout the printed part, repeatedly. This is in fact one of the main challenges with all AM techniques today. At Procada we are therefore specialized in automation and closed-loop process control of metal-wire DED. Our solutions ensure that key process variables are maintained within a qualified process window at all times, resulting in printed parts with highest material integrity. Additionally, our closed-loop control systems support arbitrary deposition patterns including all wire feeding directions. This unique ability of our control systems means that the DED process can now be optimized for each part or feature to be printed. Printing speed does not longer come at the sacrifice of part resolution.

Markets

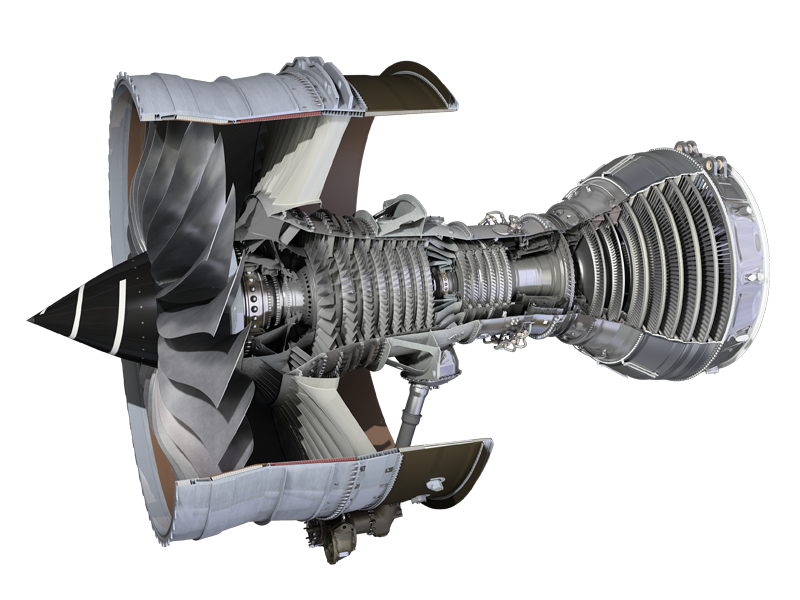

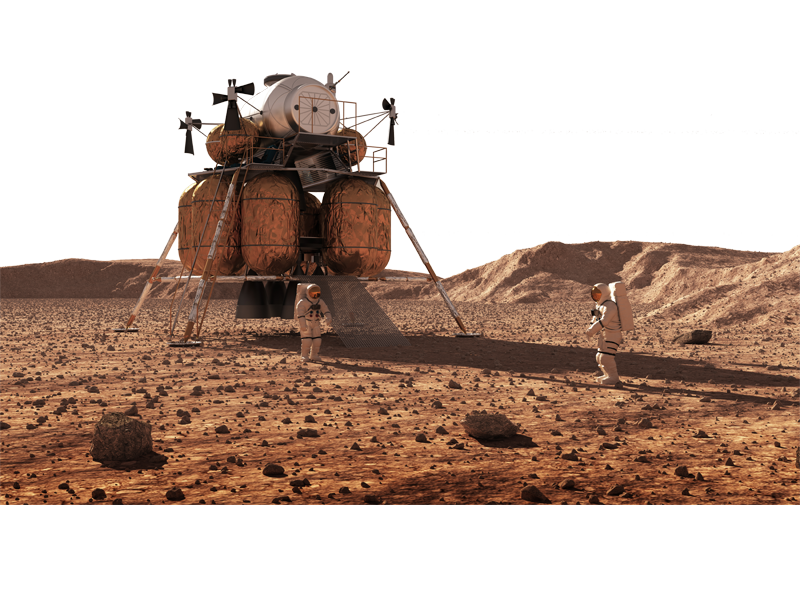

With our closed-loop control solutions the number of valuable applications for DED extends largely beyond the current use of manually controlled prototyping or low volume production of large yet simple parts. Below we have listed several segments where we see an expanding number of feasible applications for closed-loop controlled wire DED resulting in substantial returns on investment.