First time right - every time

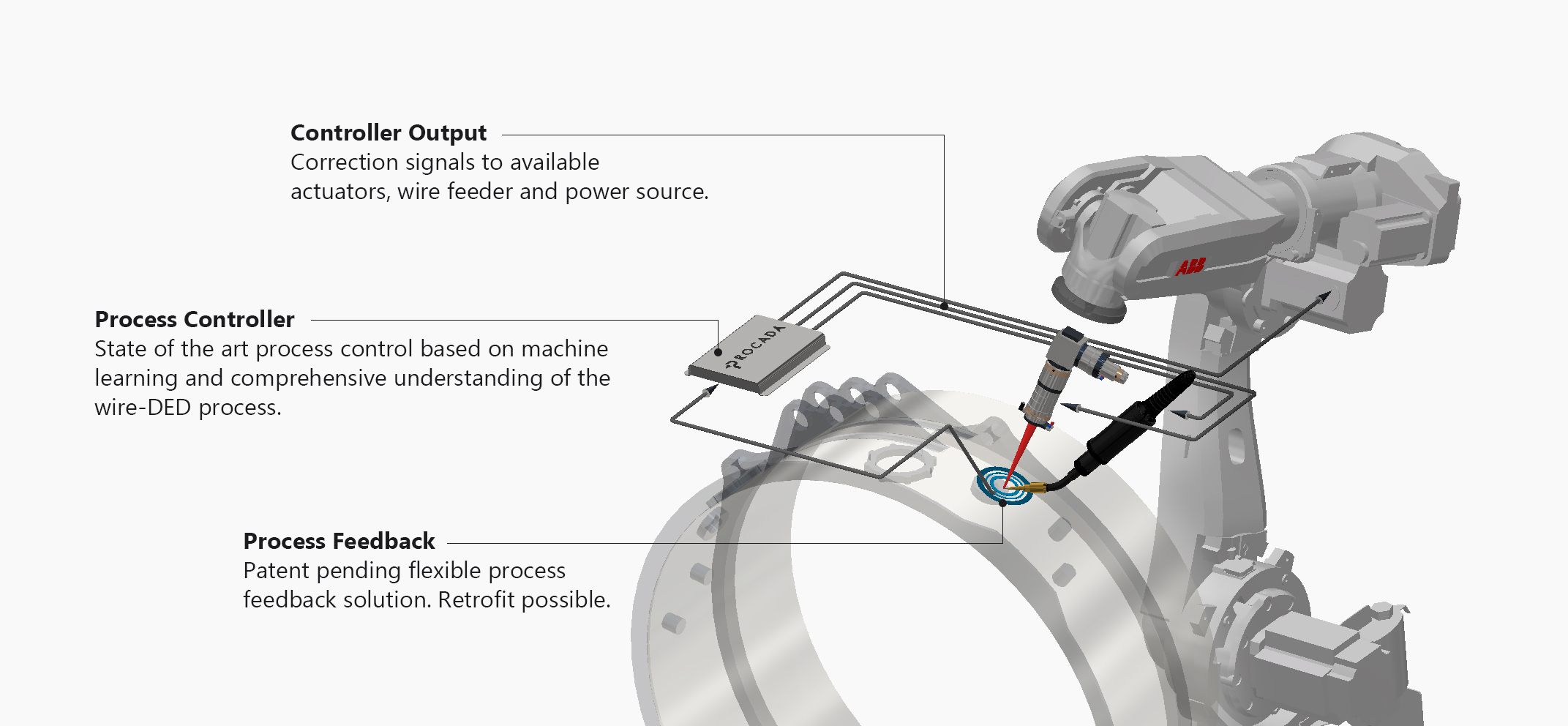

With Procada’s patent pending closed-loop control solution it is now possible to monitor and control key process variables during the entire deposition process. This will ensure specified material integrity and geometrical tolerances throughout the printed part, every time.

We offer reliability, robustness and repeatability

Why closed-loop control? Directed Energy Deposition process requires around 25 parameters to be set before a deposition sequence can take place. During deposition however the process will inevitably experience disturbances which needs to be compensated for if material integrity is to be ensured. We take pride in having developed a process monitoring and control solution fully capable of handling the non-linear dynamics of the deposition process and the harsh melt pool environment.

Reliability

Working with additive manufacturing and high-power lasers for over a decade we know how to build durable equipment that can withstand even the toughest of applications.

Robustness

Long before a disturbance becomes critical to your process, we are able to measure it and correct for it, keeping your application within the defined process window at all times.

Repeatability

Procada’s closed-loop process control solutions enables you to achieve first-time-right, every time. This is quality assurance at its best.

Flexibility without compromise

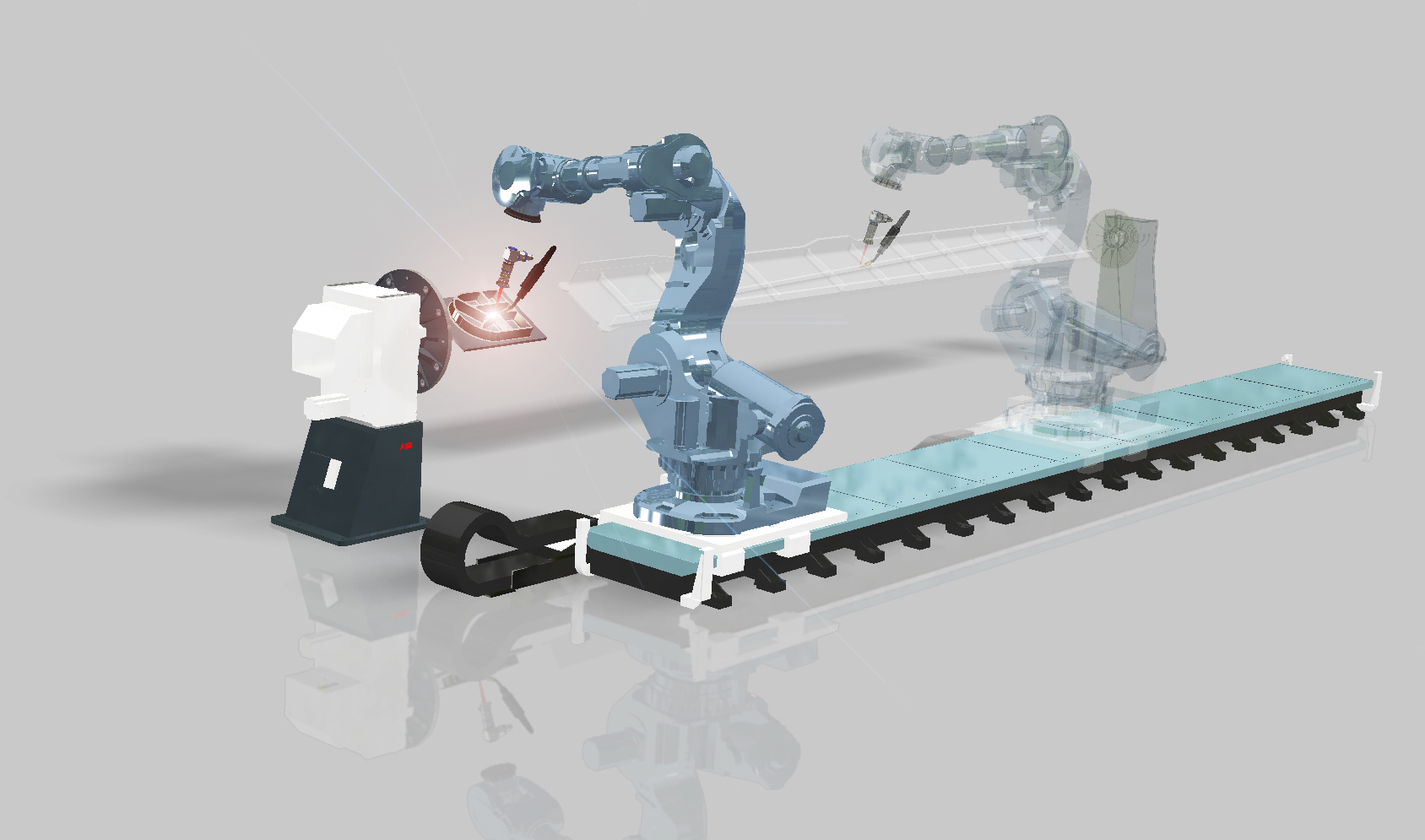

Directed Energy Deposition paired with Procada’s unique process monitoring and control solutions offers true flexibility in terms of size, shape and resolution of the parts to be printed, without compromising the material integrity.

Flexibility without compromise

Directed Energy Deposition paired with Procada’s unique process monitoring and control solutions offers true flexibility in terms of size, shape and resolution of the parts to be printed, without compromising the material integrity.

Flexibility without compromise

Directed Energy Deposition paired with Procada’s unique process monitoring and control solutions offers true flexibility in terms of size, shape and resolution of the parts to be printed, without compromising the material integrity.

Product specification

Functionality

Detect, record and compensate for process disturbancesProcess compatibility

Laser, electric arc, electron beamMaterial compatibility

Weldable metals available as wireInterface

Standard industrial interfaces such as Profinet, Profibus, Modbus, DeviceNet, EtherNet/IP, EtherCATMotion system

Standard industrial motion systems such as robots and gantry. Either PTO, PWM or proprietary controlInstallation

Retrofit to existing deposition or welding systems possibleHMI

Custom made operator interface for browser, PC or control panelAdditional SW

Data analysis and logging tools for full traceabilityTemperature feedback

Supports radiation sensors (pyrometers) and contact probes (thermocouples,Pt-100/1000, thermistors)